- arrow_back Home

- keyboard_arrow_right Technology

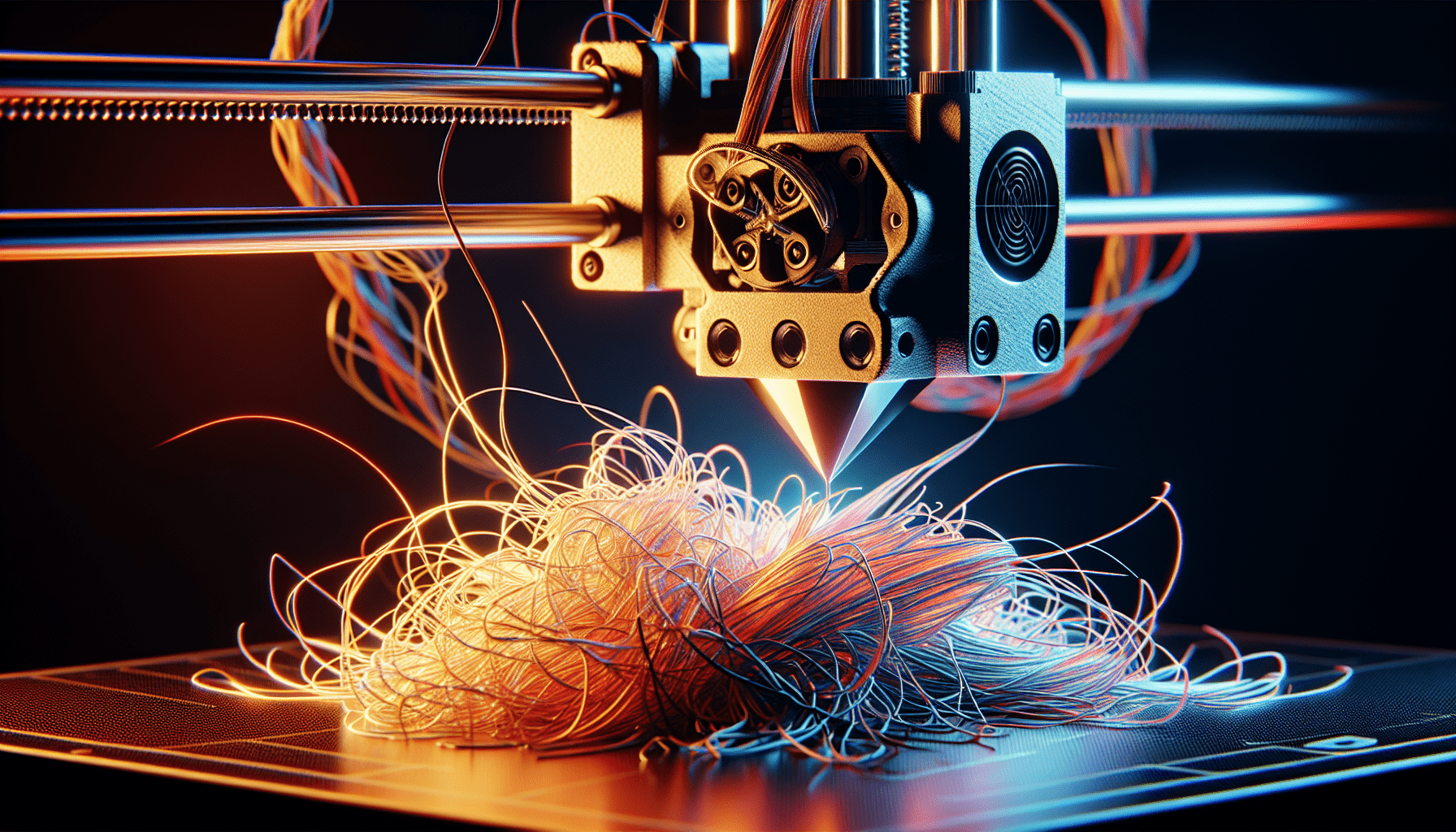

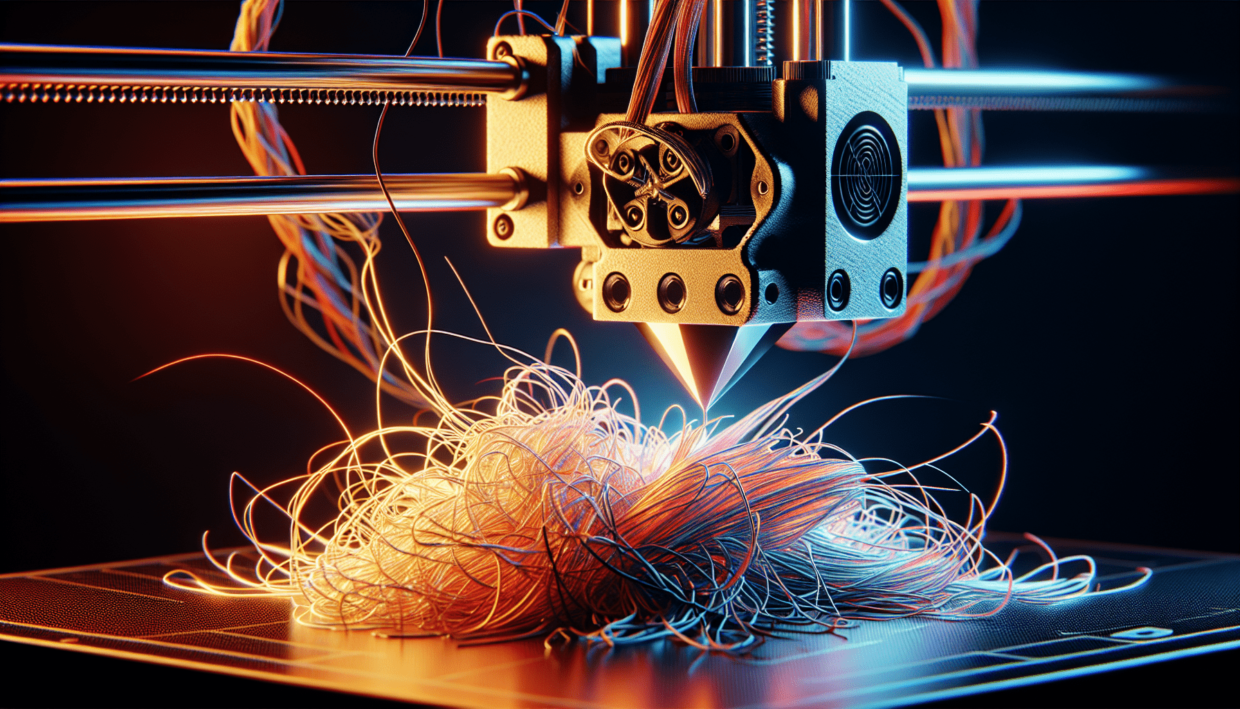

Solving Filament Clogging Issues in 3D Printing

Technology Chris Wyatt 12 June 2024

In the realm of 3D printing, you have likely encountered one of the most frustrating and recurring issues that can bring your entire production to a halt: filament clogging. This phenomenon occurs when the filament becomes stuck or obstructed within the printer’s nozzle or extruder, resulting in failed prints, wasted material, and a significant loss of productivity. As you delve into the world of additive manufacturing, it is essential to develop a comprehensive understanding of the causes and consequences of filament clogging, as well as the strategies and techniques necessary to mitigate and overcome this common problem. Are you tired of dealing with frustrating filament clogging issues in your 3D printing process? You’re not alone. Filament clogging is a common problem that can bring your entire printing operation to a standstill, wasting valuable time and resources.

Understanding Filament Clogging

What causes filament clogging?

Filament clogging occurs when the filament inside the extruder or hotend becomes blocked, preventing it from flowing freely. This blockage can be caused by a variety of factors, including moisture absorption, contamination, or simply poor quality filament.

The consequences of filament clogging

The consequences of filament clogging can be severe, resulting in failed prints, wasted materials, and expensive repairs. In some cases, clogging can even lead to damage to the extruder or hotend, requiring costly replacements.

Identifying the Source of the Clog

Inspect the filament

Before troubleshooting the clog, it’s essential to inspect the filament itself. Check for any visible signs of moisture, dust, or debris that could be contributing to the clog. Use a soft brush or cloth to gently remove any loose particles from the filament surface.

Check the extruder and hotend

Next, inspect the extruder and hotend for any signs of blockage or buildup. Remove any visible debris or residue using a soft brush or cleaning tool. It’s also a good idea to check the heatbreak and nozzle for any signs of clogging.

Common Causes of Filament Clogging

Moisture absorption

Moisture absorption is a common cause of filament clogging. When filament is exposed to high humidity or moisture, it can absorb water, causing it to swell and become more prone to clogging.

Contamination

Contamination is another common cause of filament clogging. Dirt, dust, and other particles can accumulate on the filament surface, causing blockages and clogs.

Poor quality filament

Poor quality filament can also contribute to clogging issues. Low-quality filament may contain impurities or defects that can cause it to clog more easily.

Improper storage

Improper storage of filament can also lead to clogging issues. Filament that is exposed to high temperatures, humidity, or light can become more prone to clogging.

Solutions to Filament Clogging

Dry the filament

To prevent moisture absorption, it’s essential to dry the filament before printing. This can be done using a food dehydrator or a dry box.

Clean the extruder and hotend

Regular cleaning of the extruder and hotend can help prevent clogging. Use a soft brush or cleaning tool to remove any debris or residue.

Use high-quality filament

Using high-quality filament can help reduce the risk of clogging. Look for filament from reputable suppliers that is specifically designed for 3D printing.

Properly store filament

Properly storing filament can also help prevent clogging issues. Store filament in a cool, dry place, away from direct sunlight and moisture.

Use a filament dryer

A filament dryer is a device that removes moisture from the filament, making it less prone to clogging. These devices can be especially useful in humid environments.

Troubleshooting Clogs

Method 1: Cold pull

The cold pull method involves heating the extruder to the recommended temperature, then quickly removing the filament. This can help dislodge any blockages or debris.

Method 2: Heat soak

The heat soak method involves heating the extruder to a high temperature (around 250°C) for an extended period. This can help soften and dislodge any blockages.

Method 3: Drill out the clog

In extreme cases, it may be necessary to drill out the clog using a drill bit. This should only be done as a last resort, as it can damage the extruder or hotend.

Preventing Future Clogs

Regular maintenance

Regular maintenance of the extruder and hotend can help prevent clogs from forming in the first place. Regularly clean and inspect the extruder and hotend to prevent buildup and blockages.

Use a moisture-absorbing material

Using a moisture-absorbing material, such as silica gel, can help prevent moisture absorption and clogging.

Store filament properly

Properly storing filament can also help prevent clogs. Store filament in a cool, dry place, away from direct sunlight and moisture.

Monitor filament quality

Monitoring the quality of your filament can also help prevent clogs. Check filament regularly for signs of contamination or poor quality.

| Method | Description | Effectiveness |

|---|---|---|

| Cold pull | Remove filament while hot | 7/10 |

| Heat soak | Heat extruder to high temperature | 8/10 |

| Drill out clog | Drill out blockage with drill bit | 5/10 |

By following these steps and solutions, you can reduce the risk of filament clogging and ensure successful prints. Remember to stay vigilant and maintain your 3D printer regularly to prevent clogs from forming in the first place.

About Ultimate 3D

Learn everything there is to know about 3D Printers and the different components and printing materials.

Site Links

Copyright 2024 Ultimate 3D

Be the first to leave a comment