- arrow_back Home

- keyboard_arrow_right Technology

Reduce Costs with 3D Printing

Technology Chris Wyatt 9 June 2024

In the rapidly evolving landscape of manufacturing and production, 3D printing emerges as a transformative technology that offers substantial cost-saving opportunities. This article delves into the various ways by which 3D printing can significantly reduce your production expenses. By leveraging this innovative technology, you can efficiently produce prototypes and final products, create essential tools, and design custom works with precision—all at a fraction of the cost compared to traditional methods. Embrace 3D printing to gain a competitive edge through reduced overheads and enhanced design flexibility. Have you ever wondered how you could reduce production costs without sacrificing quality or customization? In a world where operational efficiency and cost-cutting measures are paramount, industries across the globe are investing in innovative technologies. One such game-changer is 3D printing, also known as additive manufacturing. This revolutionary technology offers an array of advantages that can help you significantly reduce your costs while maintaining, or even improving, the quality of your products.

Understanding 3D Printing

3D printing is a transformative approach to manufacturing. Unlike traditional methods that involve subtractive processes (cutting, drilling, etc.), 3D printing is an additive process that builds objects layer by layer from digital models. This allows for unprecedented precision and flexibility in creating complex geometries and customized parts.

Key Components of 3D Printing

-

Materials

- Polymers: Commonly used for prototyping and some end-use parts.

- Metals: Used for high-strength applications.

- Ceramics: Ideal for high-heat components.

- Composites: Offer a mix of properties from different materials.

-

Equipment

- Printers: Vary from desktop models for hobbyists to industrial-grade machines.

- Software: CAD (Computer-Aided Design) programs for designing parts.

- Post-processing Tools: For finishing parts once printed.

-

Processes

- SLA (Stereolithography): Uses light to cure resin layer by layer.

- SLS (Selective Laser Sintering): Uses a laser to fuse powder materials.

- FDM (Fused Deposition Modeling): Extrudes melted material to form layers.

- DMLS (Direct Metal Laser Sintering): Similar to SLS but for metal powders.

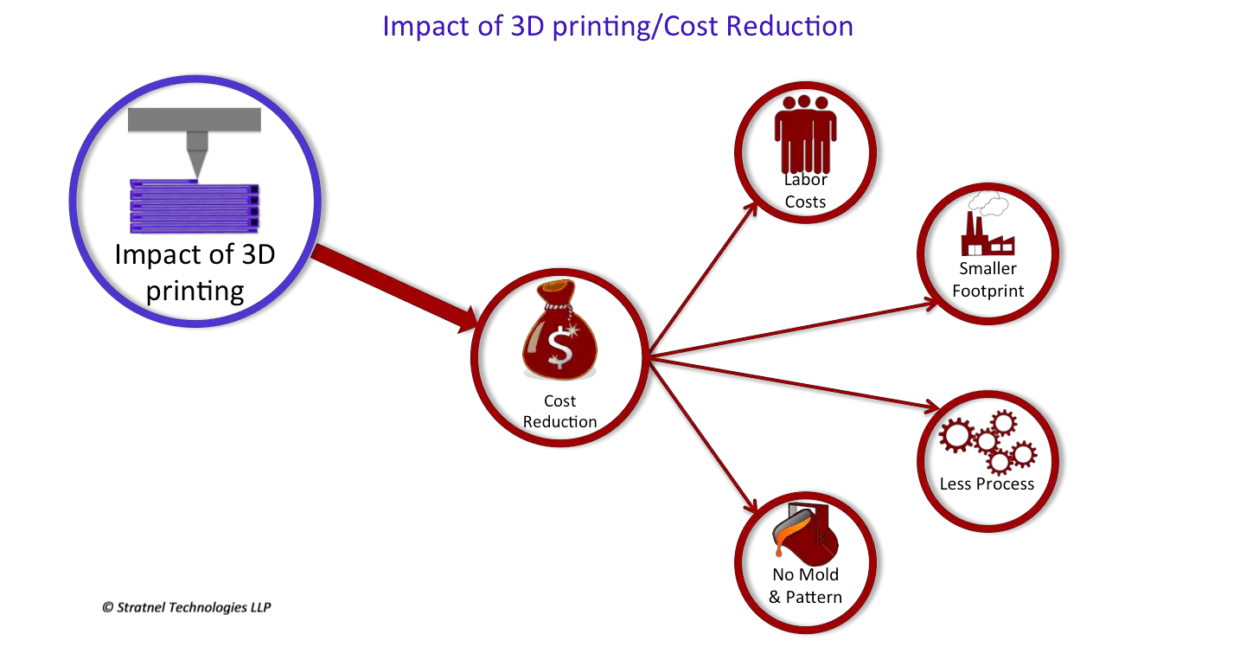

Benefits of 3D Printing

3D printing offers several compelling advantages:

- Cost Reduction: Lower material waste, reduced need for labor, and minimized overhead costs.

- Customization: Easily make bespoke parts tailored to specific requirements.

- Speed: Rapid prototyping and quicker time-to-market.

- Complexity: Ability to produce intricate designs that are difficult or impossible with traditional methods.

Lowering Production Costs with 3D Printing

Cost-Effective Prototyping

One of the primary applications of 3D printing is in prototyping. Traditional prototyping methods can be both time-consuming and expensive, often requiring custom tooling and molds. With 3D printing, you can create prototypes directly from CAD files in a fraction of the time and cost.

Comparison of Prototyping Costs:

| Method | Cost (USD) | Time (Days) |

|---|---|---|

| Traditional Molding | $5,000-$10,000 | 7-30 |

| CNC Machining | $1,000-$3,000 | 5-10 |

| 3D Printing | $100-$1,000 | 1-3 |

By adopting 3D printing for prototyping, you can reduce upfront costs and iterate designs more efficiently. This not only accelerates product development but also enhances the final output by allowing more room for trial and error without significant financial impact.

Producing Custom and Low-Volume Parts

Manufacturing custom or low-volume parts traditionally incurs high costs due to the need for specific molds or tooling. However, 3D printing excels in this area by eliminating the need for such preparations. You can produce parts on-demand, tailored precisely to specification, without incurring extra costs for unique molds or minimum order quantities.

Advantages in Custom Production:

- No Tooling Costs: Digital manufacturing eliminates the need for expensive and time-consuming mold creation.

- Flexible Production Runs: Whether you need one piece or a hundred, the cost per unit remains consistent.

- Rapid Modifications: Changes can be implemented immediately in the design software and sent directly to the printer.

Reduced Material Waste

Traditional manufacturing methods often result in substantial material waste due to the subtractive nature of the processes. Conversely, 3D printing uses only the material needed to create the part, significantly reducing waste.

Material Utilization Comparison:

| Manufacturing Method | Material Utilization Efficiency (%) |

|---|---|

| CNC Machining | 30-50% |

| Casting | 50-70% |

| 3D Printing | 80-95% |

Reduced material waste translates to lower costs, especially when working with expensive materials like metals and composites. This efficiency also contributes to more sustainable manufacturing practices, aligning well with global environmental goals.

Printing Useful Tools and Fixtures

Another way 3D printing can lower costs is by producing the tools and fixtures needed for manufacturing in-house. Instead of purchasing expensive, off-the-shelf items or commissioning custom tools, you can print what you need when you need it.

Examples of Printable Tools and Fixtures:

- Jigs: Custom-designed to hold specific parts securely in place during assembly.

- Fixtures: Used for positioning components accurately.

- Gauges: For quick and precise measurements.

- Templates: Custom patterns to guide manual work processes.

This flexibility reduces downtime and ensures that your manufacturing operations run smoothly without waiting for externally sourced tools to arrive.

Enhancing Product Design and Performance

Complex and Intricate Designs

3D printing allows you to create complex and intricate designs that are challenging, if not impossible, with traditional manufacturing methods. You can incorporate features such as internal channels for cooling systems, lightweight lattices, and complex geometries, all of which can enhance the performance and functionality of your products.

Examples of Complex Design Applications:

- Aerospace: Lightweight structures with complex internal geometries.

- Medical: Customized prosthetics and implants tailored to individual patients.

- Automotive: Custom parts and components optimized for performance.

Personalization and Customization

In today’s market, personalization is a key differentiator. Consumers and clients increasingly seek products tailored to their specific preferences and needs. 3D printing provides an efficient way to offer this level of customization without driving up costs significantly.

Benefits of Personalization:

- Customer Satisfaction: Greater satisfaction by meeting specific requirements.

- Brand Loyalty: Personalized products can enhance brand loyalty and customer retention.

- Market Segmentation: Cater to niche markets effectively.

Rapid Iteration and Testing

The ability to quickly iterate and test different designs is an invaluable advantage offered by 3D printing. Rather than investing weeks or months into a traditional manufacturing cycle only to find a design flaw, you can rapidly produce, test, and modify prototypes in days.

Iteration Process:

- Design: Create or update your CAD model.

- Print: Produce the prototype using 3D printing.

- Test: Evaluate the prototype for form, fit, and function.

- Modify: Adjust the design based on test results and repeat the cycle as necessary.

By accelerating the iteration process, you save both time and money, and enhance your product development lifecycle. This rapid testing regime helps identify and address issues early, resulting in a more polished final product.

Efficient Inventory Management and Supply Chain Optimization

On-Demand Production

One significant cost-saving factor of 3D printing is its potential to revolutionize inventory management. On-demand production reduces the need for large warehouses and the associated costs of storing unused inventory.

Benefits of On-Demand Production:

- Reduced Storage Costs: Minimize warehousing needs.

- Decreased Obsolescence: Produce parts as required, reducing the chance of outdated stock.

- Enhanced Agility: Quickly respond to changes in market demand.

Shortening the Supply Chain

By producing parts closer to the point of use, 3D printing can shorten supply chains and reduce logistics costs. This decentralization means that parts can be produced locally, thereby reducing shipping costs and lead times.

Impact on Supply Chain:

- Local Manufacturing: Production facilities closer to end-users.

- Faster Delivery: Shortened lead times to market.

- Cost Savings: Lowered transportation and storage costs.

Spare Parts and Maintenance

Effective maintenance and the availability of spare parts are critical to operational efficiency. 3D printing allows for the rapid production of spare parts, reducing the downtime associated with broken or worn-out components. This capability is particularly beneficial in industries such as manufacturing, transportation, and healthcare.

Advantages for Spare Parts Production:

- Immediate Availability: Print parts as needed.

- Cost-Effective: Avoid overstocking spare parts that may never be used.

- Customization: Produce modified parts to improve performance or address specific issues.

Case Studies and Real-World Applications

Manufacturing Industry

In the automotive industry, companies like BMW and Ford have adopted 3D printing to produce custom tools and parts that would otherwise be too costly or time-consuming to manufacture traditionally. By doing so, they have significantly cut down on production costs and reduced lead times.

Medical Field

The medical field has particularly benefited from 3D printing, with hospitals and medical device manufacturers being able to produce patient-specific implants, prosthetics, and surgical guides. This customization improves patient outcomes and reduces the costs associated with mass-producing standard devices.

Aerospace Sector

The aerospace industry has leveraged 3D printing to create lightweight, high-strength components. Companies like Boeing and Airbus have used 3D printing to produce parts that are not only lighter but also more durable, reducing fuel costs and enhancing performance metrics.

Consumer Goods

In the consumer goods industry, companies like Adidas have used 3D printing to create customized athletic footwear. This not only reduces waste but also allows for rapid prototyping and production, keeping them ahead of trends and customer demands.

Challenges and Considerations

While 3D printing offers numerous advantages, it is essential to be aware of the challenges and considerations involved.

Initial Investment Costs

Although 3D printing offers long-term cost savings, the initial investment in equipment and training may be substantial. High-quality industrial 3D printers can be expensive, and your staff will need proper training to operate and maintain them.

Material Limitations

Not all materials are suitable or available for 3D printing. While the range of printable materials is expanding, some applications may still require traditional manufacturing techniques due to material constraints.

Post-Processing Requirements

Printed parts often require post-processing to achieve the desired finish or mechanical properties. This can add time and cost to the production process. Common post-processing steps include cleaning, curing, machining, and painting.

Intellectual Property Concerns

With the ability to easily replicate designs, there is a risk of intellectual property infringement. Ensuring that proprietary designs are protected and not easily copied or distributed is crucial.

Regulatory Compliance

In industries like healthcare and aerospace, components must meet stringent regulatory and quality standards. Ensuring that 3D printed parts comply with these regulations can be challenging and may require rigorous testing and validation.

Future Trends in 3D Printing

Advancements in Materials

Research and development are continually expanding the range of materials suitable for 3D printing. From biocompatible materials for medical applications to high-strength alloys for aerospace, the possibilities are growing.

Hybrid Manufacturing

Combining 3D printing with traditional manufacturing techniques can offer the best of both worlds. Hybrid manufacturing approaches can optimize production efficiency, improve material properties, and broaden the scope of what can be produced.

Increased Adoption

As technology improves and costs decrease, more industries will adopt 3D printing as a standard manufacturing method. From small businesses to large enterprises, the benefits of rapid, on-demand production will drive broader implementation.

Sustainable Manufacturing

With a focus on reducing waste and utilizing eco-friendly materials, 3D printing is poised to play a significant role in sustainable manufacturing practices. Innovations in recycling printed materials and utilizing bio-degradable resources are on the horizon.

Automation and Integration

Future advancements will likely see greater automation and integration of 3D printing processes within smart factories. This will enhance efficiency, reduce human error, and further drive down costs.

Conclusion

3D printing is more than just a novelty or a tool for prototyping; it is a transformative technology with the potential to significantly reduce costs across various aspects of production and supply chain management. From the creation of custom and low-volume parts, reducing material waste, and the rapid iteration of prototypes, to the efficient management of inventory and supply chains, 3D printing offers a myriad of advantages.

While challenges exist, ongoing advancements in materials, processes, and technology are rapidly addressing these issues, paving the way for broader and more effective adoption.

By integrating 3D printing into your operations, you can achieve substantial cost savings, improve product design and performance, and enhance your overall production efficiency. Whether you are in manufacturing, healthcare, aerospace, or consumer goods, the strategic implementation of 3D printing technology can provide a significant competitive edge in today’s fast-paced market environment.

About Ultimate 3D

Learn everything there is to know about 3D Printers and the different components and printing materials.

Site Links

Copyright 2024 Ultimate 3D

Be the first to leave a comment