- arrow_back Home

- keyboard_arrow_right 3D Printing

Exploring Digital Light Processing (DLP) in 3D Printing

3D Printing Chris Wyatt 3 June 2024

Welcome to a fascinating journey into the world of 3D printing, specifically focusing on Digital Light Processing (DLP). In this article, you’ll explore how this innovative technology stands out among various 3D printing methods, which typically include Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS). You’ll delve into the unique mechanisms of DLP, which uses photopolymers instead of traditional filaments, and uncover the specific safety measures you need to keep in mind when working with these materials. So, let’s dive into the intricate and captivating universe of DLP 3D printing! Have you ever wondered how 3D printers work their magic to transform digital designs into tangible objects? Let’s embark on an exploration of one fascinating technology within the realm of 3D printing: Digital Light Processing (DLP).

Understanding the Basics of 3D Printing

Before diving into DLP, it’s essential to understand the broader world of 3D printing. 3D printing, also known as additive manufacturing, is a process where digital models are brought to life by adding material layer by layer. This revolutionary technology has a multitude of applications ranging from prototyping to manufacturing end-use products.

Types of 3D Printers

There are several types of 3D printers, each with its unique strengths, materials, and use cases. By familiarizing yourself with these types, you’ll appreciate what sets DLP apart.

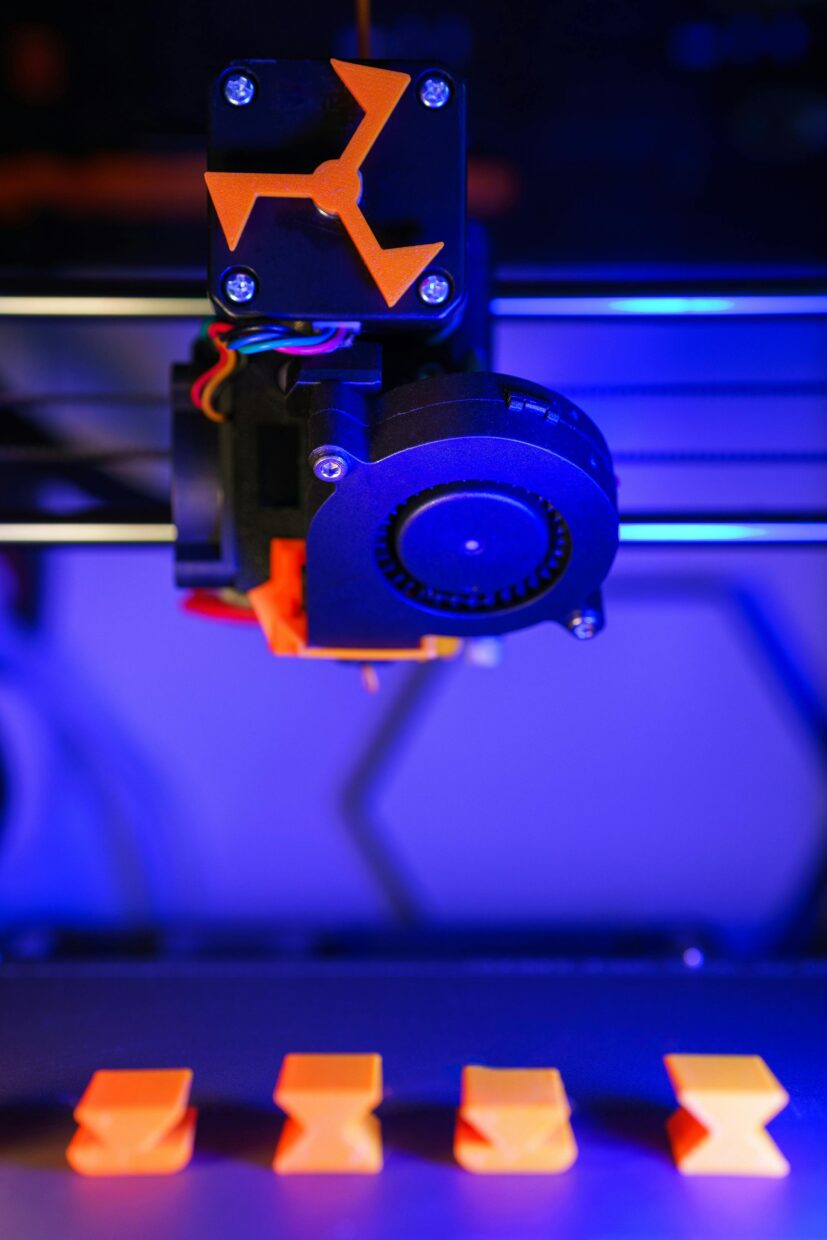

Fused Deposition Modeling (FDM)

FDM is perhaps the most well-known type of 3D printing. FDM machines work by heating and extruding thermoplastic filaments through a nozzle. The printer lays down the material in thin layers to create the final object.

| Feature | Details |

|---|---|

| Materials Used | PLA, ABS, PETG, TPU, Nylon |

| Pros | Inexpensive, easy to use, accessible |

| Cons | Lower resolution, visible layer lines |

| Safety Concerns | Fumes from heating plastics, burn risks |

Stereolithography (SLA)

SLA uses a laser to cure liquid resin into hardened plastic. The laser traces each layer, solidifying the resin based on the design.

| Feature | Details |

|---|---|

| Materials Used | Photopolymer resins |

| Pros | High resolution, smooth surfaces |

| Cons | Expensive, requires post-processing |

| Safety Concerns | Resin toxicity, UV light exposure |

Selective Laser Sintering (SLS)

SLS works by sintering powdered material using a laser. The laser fuses the particles together to build the object layer by layer.

| Feature | Details |

|---|---|

| Materials Used | Nylon, polystyrene, metals |

| Pros | Strong, durable parts, no support needed |

| Cons | High cost, complex machinery |

| Safety Concerns | Powder inhalation, laser hazards |

Introduction to Digital Light Processing (DLP)

Now that we’ve covered the basics of 3D printing, let’s zoom in on Digital Light Processing (DLP). DLP is a type of 3D printing technology that uses digital light projections to cure photopolymer resins, layer by layer, to build a 3D object.

How Does Digital Light Processing (DLP) Work?

DLP relies on a digital light projector to flash a complete image of each layer across a vat of liquid resin. This resin reacts to the light, hardening instantaneously. The process continues layer by layer until the whole object is formed.

Step-by-Step Process

- Digital Model Preparation: Start with a digital 3D model created using CAD software. This model is then sliced into numerous thin layers.

- Liquid Resin Vat: Fill the printer’s vat with liquid photopolymer resin. This resin is sensitive to light and will cure when exposed.

- Light Projection: The projector emits light to cure a complete layer of the object at once.

- Layer Building: The build platform moves up (or the resin level drops), and the next layer is cured.

- Object Completion: This iterative process continues until the object is fully formed.

| Step | Description |

|---|---|

| Preparation | Create and slice digital model |

| Resin Fill | Fill the vat with photopolymer |

| Projection | Project light, curing resin |

| Layer Build | Move platform/resin, repeat |

| Completion | Finished 3D object |

Materials Used in DLP

DLP printers use photopolymer resins. These resins come in various formulations to achieve different mechanical and aesthetic properties.

| Type of Resin | Characteristics |

|---|---|

| Standard Resin | Good resolution, poor flexibility |

| Flexible Resin | High elasticity, rubber-like texture |

| Tough Resin | Durable, impact-resistant |

| High-Temp Resin | Withstands high temperatures |

Advantages of DLP

DLP offers several advantages that make it an attractive option for various applications.

High Resolution and Detail

One of the standout features of DLP is its ability to produce high-resolution prints with fine details. This makes it ideal for applications like jewelry, dental models, and intricate prototypes.

Speed

DLP can be faster than other 3D printing technologies, especially for detailed objects. Since the entire layer is cured at once, it reduces the build time significantly compared to methods that trace each layer individually.

| Feature | DLP |

|---|---|

| Resolution | High |

| Speed | Fast (entire layer cured at once) |

Disadvantages of DLP

Despite its benefits, DLP has some drawbacks that you should be aware of.

Limited Build Size

DLP printers typically have smaller build volumes compared to other types like FDM or SLS. This limits the size of the objects you can print.

Resin Handling

Resin handling can be messy and potentially hazardous. Many resins are toxic and require careful handling and protective gear.

| Limitation | DLP |

|---|---|

| Build Size | Generally smaller than FDM or SLS |

| Resin Handling | Messy, toxic, requires care |

Safety Precautions and Best Practices

When it comes to 3D printing, safety is paramount, especially with technologies like DLP that involve liquids and light.

Handling Resins Safely

Photopolymer resins can be toxic. Always wear gloves and work in a well-ventilated area. Be cautious not to spill resin on your skin, and clean any spills immediately using appropriate cleaning agents.

UV Exposure

DLP involves UV light which can be harmful to your eyes and skin. Avoid looking directly at the light source and wear protective eyewear if necessary.

Post-Processing

Most DLP-printed objects require post-processing, such as washing in isopropyl alcohol and additional curing. These steps also come with their set of risks and should be performed with care.

| Safety Aspect | Best Practices |

|---|---|

| Resin Handling | Use gloves, ventilated areas, clean spills promptly |

| UV Exposure | Avoid direct exposure, use protective eyewear |

| Post-Processing | Follow instructions, handle chemicals carefully |

Applications of DLP in Various Industries

DLP’s unique capabilities make it suitable for a wide range of applications across different industries.

Jewelry

The high resolution and fine detail offered by DLP make it perfect for creating intricate jewelry designs. Jewelers can create highly detailed prototypes and molds for casting.

Dental and Medical

In the dental and medical fields, DLP is used to create accurate dental models, surgical guides, and even prosthetics. The precision and biocompatibility of certain resins are crucial in these applications.

Prototyping

For product designers and engineers, DLP can rapidly produce precise prototypes, making it easier to test and validate designs before full-scale production.

Education and Research

Educational institutions use DLP printers to teach students about 3D printing technology, while researchers employ them to create models for various experiments.

| Industry | Application |

|---|---|

| Jewelry | Prototyping, casting molds |

| Dental/Medical | Dental models, surgical guides |

| Prototyping | Design validation |

| Education | Teaching, research models |

Future Trends in DLP 3D Printing

The world of DLP 3D printing is evolving rapidly. Several future trends promise to enhance its capabilities further.

Enhanced Speed and Resolution

Continuous improvements in projector technology will likely lead to even higher resolution and faster printing speeds, making DLP more competitive with traditional manufacturing methods.

New Resin Formulations

Development of new resin formulations with enhanced properties such as improved toughness, biocompatibility, and heat resistance will expand the range of applications.

Portable and More Affordable Models

As technology matures, expect to see more affordable and portable DLP printers, making this technology accessible to a broader audience, from hobbyists to small businesses.

Integration with Other Technologies

Integration with other technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) could lead to smarter printers that can optimize print settings in real-time for better results.

| Future Trend | Potential Impact |

|---|---|

| Enhanced Speed/Resolution | Better quality, reduced time |

| New Resin Formulations | Broader application range |

| Affordable Models | Wider accessibility |

| Tech Integration | Smarter, optimized printing |

Conclusion

Digital Light Processing (DLP) is a powerful and versatile 3D printing technology. With its high resolution, speed, and growing range of materials, DLP is addressing needs across industries from jewelry to medical. However, it comes with its challenges, and staying safe while handling resins and operating printers is crucial.

As technology advances, DLP is expected to become even more efficient, accessible, and versatile, making it an exciting area to follow and explore. Whether you’re a hobbyist, a professional, or simply curious, DLP offers a window into the cutting-edge world of 3D printing. So, why not dive in and start experimenting?

About Ultimate 3D

Learn everything there is to know about 3D Printers and the different components and printing materials.

Site Links

Copyright 2024 Ultimate 3D

Be the first to leave a comment