- arrow_back Home

- keyboard_arrow_right 3D Printing

Direct Drive Vs Bowden Feed

3D Printing Chris Wyatt 1 July 2024

You find yourself at the crossroads of advancing your 3D printing capabilities and are confronted with the decision between a Direct Drive and a Bowden Feed system. Direct Drive systems provide exceptional control and precision by placing the extruder close to the hot end, making it ideal for flexible filaments. On the other hand, Bowden Feed systems offer the advantage of reduced moving mass, which enhances speed and agility, especially for larger prints. Understanding the nuances of these two feeder types and their compatibility with various machines will empower you to choose the system that aligns perfectly with your specific printing needs and aspirations. Have you ever wondered which 3D printer setup is best for your needs—Direct Drive or Bowden Feed? Choosing between these two can significantly impact your printing experience and the quality of your prints. Let’s delve into the details to help you make an informed decision.

Understanding Direct Drive and Bowden Feed

What is a Direct Drive System?

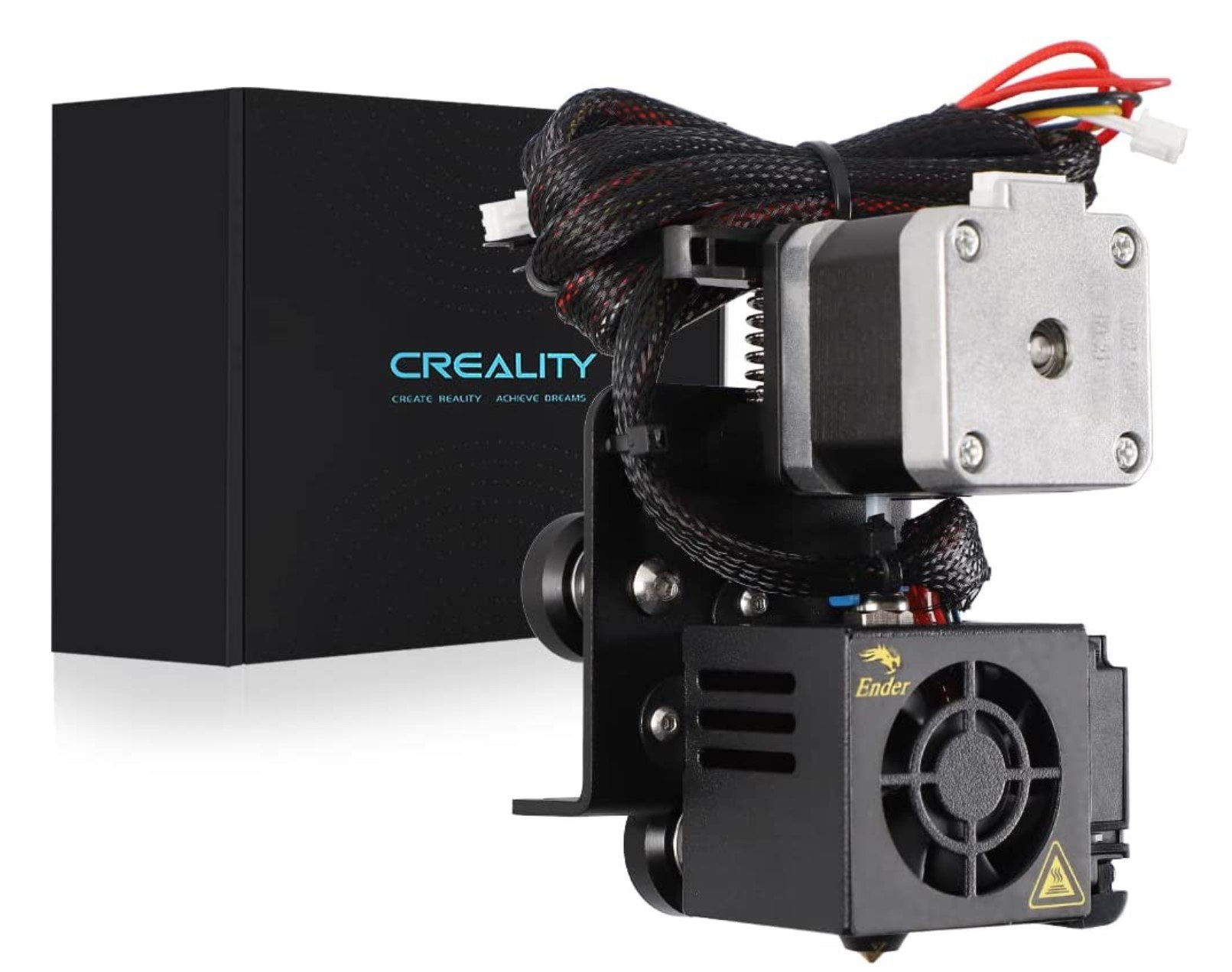

In a Direct Drive system, the extruder is mounted directly on the print head. This setup means that the motor, which pushes the filament through the hot end, is only a few centimeters away from the nozzle. Because of this proximity, the filament has less distance to travel from the extruder gears to the hot end, making for a more controlled extrusion process.

Advantages of Direct Drive

- Improved Filament Control: Direct Drive systems provide better control over filament retraction, reducing stringing and blobbing.

- Versatile Filament Types: This setup is ideal for flexible filaments like TPU, TPE, and other soft materials.

- Precision: Enhanced accuracy in extrusion can lead to higher quality prints, especially with complex layers.

Disadvantages of Direct Drive

- Weight: The added weight on the print head can slow down print speeds and reduce overall printer efficiency.

- Complexity: More moving parts can mean more maintenance and potential issues.

What is a Bowden Feed System?

In a Bowden Feed system, the extruder is mounted on the frame of the printer rather than the print head. The filament is pushed through a long PTFE tube (also known as the Bowden tube) from the extruder to the hot end, which is located on the moving print head.

Advantages of Bowden Feed

- Lightweight Print Head: Because the extruder motor is off the print head, the reduced weight allows for faster movement and higher print speeds.

- Simplified Maintenance: Fewer moving parts on the print head can lead to decreased wear and tear and easier maintenance.

- Print Quality at Speed: Allows faster movements and quick transitions between layers, improving print quality.

Disadvantages of Bowden Feed

- Retracted Filament Control: It’s less effective for flexible filaments due to the longer distance the filament travels, which can lead to less precise retractions.

- More Stringing: Less effective control over retractions can result in increased stringing and blobbing.

Machine Compatibility

Direct Drive Compatibility

Direct Drive systems are often found in high-end or specialized 3D printers, particularly those designed for detailed work or use with flexible filaments. These printers are typically more expensive due to the complexity and precision required in their construction.

Bowden Feed Compatibility

Bowden Feed systems are more common in budget-friendly and mid-range 3D printers. Their simpler construction and faster print capabilities make them ideal for large-scale, fast-printing operations, although they might struggle with specific filament types.

Comparing Direct Drive and Bowden Feed: Key Factors

Filament Types

| Filament Type | Direct Drive | Bowden Feed |

|---|---|---|

| PLA, ABS | Excellent | Excellent |

| TPU, TPE | Excellent | Poor/Fair |

| PETG | Excellent | Good |

| Nylon | Excellent | Good |

Print Speed

| Speed Requirement | Direct Drive | Bowden Feed |

|---|---|---|

| Low/Moderate | Good | Excellent |

| High Speed | Fair | Excellent |

Print Accuracy

| Accuracy | Direct Drive | Bowden Feed |

|---|---|---|

| High Accuracy | Excellent | Good |

| General Usage | Good | Good |

Maintenance

| Maintenance Type | Direct Drive | Bowden Feed |

|---|---|---|

| Frequent | More Complexity | Less Complexity |

| Infrequent | Moderate | Easy |

Which One Should You Choose?

Consider Your Printing Needs

When deciding between Direct Drive and Bowden Feed, you should consider what you’ll predominantly use your 3D printer for. Are you focused on detailed projects requiring precision and flexibility, or are you interested in speed and efficiency for general or large-scale projects?

Budget and Upfront Costs

Direct Drive systems tend to be more expensive due to their complexity and the additional features they offer. On the other hand, Bowden Feed systems are usually more budget-friendly and can be easier to find in the market for those looking for an entry-level or moderately priced 3D printer.

Filament Versatility

If you plan to use a wide range of filament types, including flexible filaments, a Direct Drive might be the way to go. However, if you’re sticking mostly with PLA, ABS, or other common filaments, a Bowden Feed should suffice.

Long-Term Maintenance

Consider how much time you’re willing to spend on maintenance. Direct Drive systems require more frequent upkeep due to their more complex mechanics, whereas Bowden Feed systems are simpler and generally easier to maintain.

Real-World Applications and Scenarios

Professional Use

For professionals in fields like dentistry, jewelry, or any other industry requiring high precision and detail, the Direct Drive system is more suitable. The fine control over filament retraction and the ability to handle flexible filaments make it ideal for intricate work.

Hobbyists and Makers

If you’re a hobbyist looking for a versatile machine that can handle a variety of projects, you might lean towards Bowden Feed for its simplicity and speed. You can still achieve high-quality prints with the right settings and some trial and error.

Educational Purposes

Educational institutions often require reliable, easy-to-maintain machines that can produce quick results for various student projects. For this setup, a Bowden Feed system is generally the better option due to its simplicity and speed.

Direct Drive and Bowden Feed: Myths and Misconceptions

Myth: Bowden Feeds Can’t Produce High-Quality Prints

While it’s true that Bowden Feed systems might struggle with some types of filaments or under specific conditions, they can still produce excellent quality prints with the right settings and adjustments.

Myth: Direct Drive is Always Better

Direct Drive systems offer enhanced control and versatility, but they’re not always superior. Depending on your needs, a Bowden Feed system might be more practical, especially if speed and ease of maintenance are your priorities.

Setting Up for Success: Tips for Each System

Optimizing Your Direct Drive Setup

- Tuning Retractions: Given that Direct Drives excel at precise retraction, spend time fine-tuning retraction settings to minimize stringing.

- Regular Maintenance: Keep an eye on the additional moving parts and perform regular checks to ensure everything is functioning smoothly.

- Flexible Filament Settings: Use the unique capabilities of Direct Drive to experiment with flexible filaments, ensuring you adjust speed and temperature settings appropriately.

Optimizing Your Bowden Feed Setup

- Bowden Tube Care: Ensure the Bowden tube is in good condition and replace it as needed to maintain smooth filament feeding.

- Retraction Adjustments: Since retraction can be less precise, spend time fine-tuning these settings to strike the right balance.

- Print Speed and Temperature: Take advantage of the reduced weight on the print head to push the limits of your print speed while also monitoring temperature settings for optimal results.

Conclusion

Navigating the world of 3D printing can be complex, especially when deciding between Direct Drive and Bowden Feed systems. Each system has its own set of strengths and weaknesses, making them more or less suitable depending on your specific needs and circumstances.

Direct Drive systems provide unparalleled control and versatility, especially with flexible filaments and detailed prints. However, they can be more complex and require more maintenance. Bowden Feed systems, on the other hand, offer speed, simplicity, and ease of maintenance but may require more adjustments to achieve the same level of print quality, particularly with flexible filaments.

By assessing your specific needs, from the types of filaments you plan to use to your desired print speed and maintenance capabilities, you can make a more informed decision. Remember, the best setup for you is one that aligns with your unique requirements and helps you achieve your 3D printing goals efficiently and effectively.

About Ultimate 3D

Learn everything there is to know about 3D Printers and the different components and printing materials.

Site Links

Copyright 2024 Ultimate 3D

Be the first to leave a comment