- arrow_back Home

- keyboard_arrow_right 3D Printers

Different types of 3D Printers: A Comprehensive Guide for Beginners

3D Printers Chris Wyatt 5 June 2024

Curious about 3D printers? Dive into our beginner-friendly guide that explores different types of 3D printers and their best uses, all explained in a casual tone!

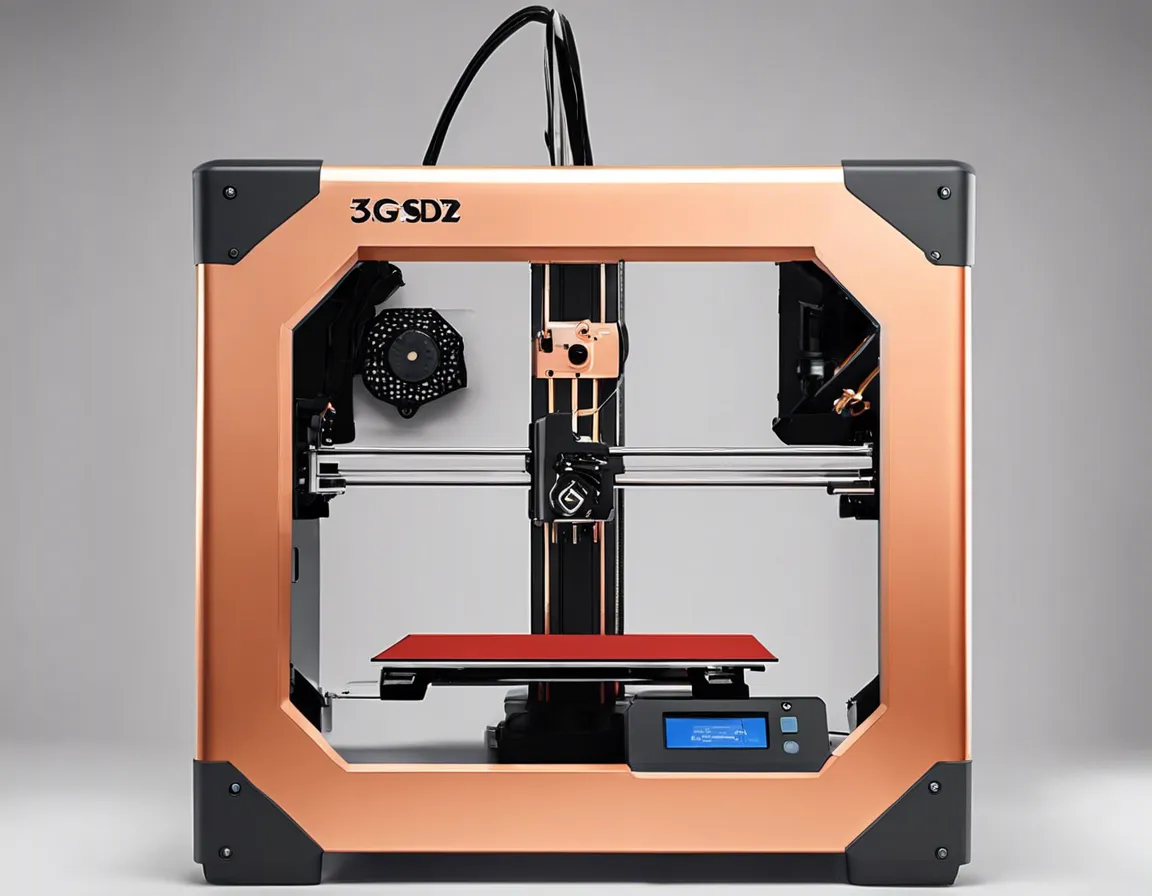

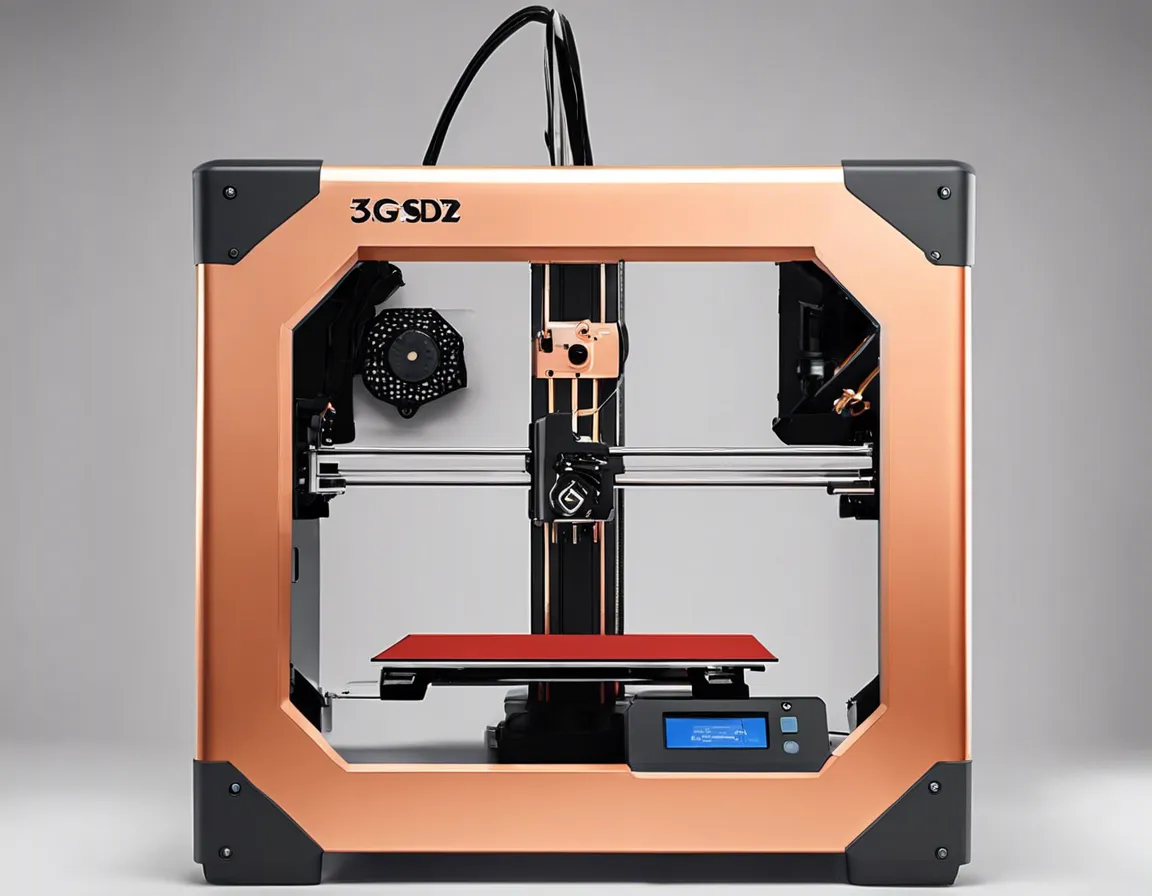

FDM Printers

FDM printers are incredibly popular among hobbyists and those just getting into 3D printing. They utilize filament to build up layers, making them an excellent choice for prototyping. Plus, they’re relatively affordable, making them accessible to a wide range of users.

One of the key advantages of FDM printers is their versatility. You can use a variety of filament types, including PLA, ABS, and PETG, each offering different properties for your projects. This flexibility allows for endless creativity and experimentation with your 3D prints.

Another great thing about FDM printers is their ease of use. Many models come with user-friendly interfaces and plenty of online resources to help you get started. Whether you’re a beginner or a seasoned maker, FDM printers provide a fantastic way to bring your ideas to life.

SLA Printers

SLA printers stand out for their ability to produce high-resolution prints, making them perfect for detailed projects like jewelry and intricate designs. Their use of resin and UV light ensures precision and smooth finishes that other 3D printers might struggle to achieve.

When it comes to 3D printers, SLA models are often preferred for their accuracy and capability to handle complex geometries. The resin-based technology allows for the creation of fine details that are crucial in fields like dentistry and custom art pieces.

With an SLA printer, you can bring your most detailed and imaginative designs to life. Whether you’re crafting custom jewelry or detailed prototypes, the combination of resin and UV light provides unmatched detail and surface quality. Dive into the world of 3D printing with confidence!

SLS Printers

SLS printers are game-changers in the 3D printing world, using powdered materials and lasers to create strong, functional parts. Unlike other 3D printers, they don’t need support structures, making the process smoother and more efficient for users.

If you’re looking for durability, SLS printers are your go-to. Perfect for producing parts that need to withstand stress and wear, these 3D printers ensure high-quality results, ideal for prototyping and end-use production alike.

The versatility of SLS printers is unmatched. They can work with a variety of powdered materials, allowing for a range of applications. From aerospace components to medical devices, these 3D printers open up endless possibilities for innovation and creativity.

DLP Printers

DLP printers, a subtype of 3D printers, use a digital light projector to cure resin, allowing for faster print times than SLA printers. This makes them ideal for small-scale production and prototypes, delivering high-detail and precision prints with efficiency.

One of the standout features of DLP printers is their ability to produce detailed models quickly. This is particularly beneficial for industries that require rapid prototyping and intricate designs, such as jewelry making, dentistry, and miniature model production.

When it comes to 3D printers, DLP technology shines with its superior speed and precision. Users can create complex, high-resolution designs without compromising on print quality. These printers are perfect for hobbyists and professionals looking to bring detailed concepts to life swiftly.

Multi-Jet Fusion

Multi-Jet Fusion is a game-changer in the world of 3D printers, offering unmatched precision and speed. This technology produces parts with excellent surface finishes, making it ideal for industrial applications that require both functionality and aesthetics.

One of the standout features of Multi-Jet Fusion is its ability to create complex geometries effortlessly. Whether you’re designing intricate prototypes or functional end-use parts, this technology ensures high-quality outcomes every time, setting a new standard in 3D printing.

For industries looking to innovate, Multi-Jet Fusion provides a versatile solution that’s both cost-effective and efficient. The technology’s rapid production capabilities and superior material properties make it a go-to choice for businesses aiming to stay ahead in a competitive market.

Conclusion

Wrapping it up, we’ve ventured through various types of 3D printers, each with its unique benefits and best practical uses. Whether you’re into hobby projects, professional prototyping, or intricate art, there’s a 3D printer out there for you. Happy printing and may your creations come to life in the best possible way!

Questions & Answers:

Question: What makes FDM printers popular among hobbyists?

Answer: FDM printers are popular among hobbyists due to their affordability, ease of use, and versatility in using different filament types like PLA, ABS, and PETG.

Question: What are the main advantages of using FDM printers?

Answer: The main advantages of FDM printers include their affordability, versatility with different filament types, and ease of use with user-friendly interfaces and online resources.

Question: Why are SLA printers ideal for detailed projects?

Answer: SLA printers are ideal for detailed projects because they use resin and UV light to produce high-resolution prints with precision and smooth finishes, making them perfect for intricate designs like jewelry and custom art pieces.

Question: In what fields are SLA printers particularly useful?

Answer: SLA printers are particularly useful in fields like jewelry making, dentistry, and custom art pieces due to their ability to handle complex geometries and produce fine details.

Question: What is a key advantage of SLS printers over other types of 3D printers?

Answer: A key advantage of SLS printers is that they do not require support structures, making the printing process smoother and more efficient.

Question: For what applications are SLS printers most suitable?

Answer: SLS printers are most suitable for producing durable parts that need to withstand stress and wear, making them ideal for prototyping and end-use production in industries like aerospace and medical devices.

Question: How do DLP printers differ from SLA printers in terms of print speed?

Answer: DLP printers differ from SLA printers in that they use a digital light projector to cure resin, allowing for faster print times.

Question: What are the benefits of using DLP printers?

Answer: The benefits of using DLP printers include faster print times, high-detail and precision prints, making them ideal for rapid prototyping in industries like jewelry making, dentistry, and miniature model production.

Question: What sets Multi-Jet Fusion technology apart in 3D printing?

Answer: Multi-Jet Fusion technology stands out for its unmatched precision and speed, producing parts with excellent surface finishes and the capability to create complex geometries effortlessly.

Question: Why is Multi-Jet Fusion technology considered cost-effective for businesses?

Answer: Multi-Jet Fusion technology is considered cost-effective for businesses due to its rapid production capabilities, superior material properties, and ability to produce high-quality functional parts efficiently.

Read also:

About Ultimate 3D

Learn everything there is to know about 3D Printers and the different components and printing materials.

Site Links

Copyright 2024 Ultimate 3D

Be the first to leave a comment