SlicersSoftware Chris Wyatt 4 June 2024

In the world of 3D printing, the STL file stands as one of the most essential components for anyone eager to bring their digital designs to life. It serves as the bridge between creative ideas and tangible objects, converting complex 3D models into a format compatible with various slicing and CAD software. Understanding the nuances between different types of software—like modelers for creating 3D images, CAD software for detailed engineering designs, and slicers for preparing these designs for printing—plays a crucial role in achieving successful prints. Whether a hobbyist or a professional, knowing how to navigate these tools and their specific functions can significantly enhance one’s 3D printing experience. Have you ever marveled at the intricate designs produced by 3D printers and wondered how they come to life? It all begins with a special file format known as the STL file. This marvelous invention has revolutionized the way we create and manufacture objects. But what exactly is an STL file, and how does it fit into the world of 3D printing? Let’s dive into the nitty-gritty of STL files and explore the software you’ll need for a successful 3D printing experience.

What is an STL File?

An STL file, short for Standard Tessellation Language or Stereolithography, is a type of file format used in 3D printing. It represents the surface geometry of a 3D object without any color, texture, or other attributes. Essentially, an STL file slices the 3D model into a series of triangular facets, providing a simplified and highly efficient way for 3D printers to understand the shape they need to print.

History and Origin

STL files have their roots in the late 1980s when 3D Systems, a pioneering company in 3D printing, introduced the stereolithography apparatus (SLA). The STL file was developed as a means to translate the complex geometries of 3D models into a format that the SLA machine could interpret and replicate.

Structure of STL Files

STL files come in two flavors: ASCII and binary. While both serve the same purpose, they have different structural compositions.

- ASCII STL: Human-readable format, easier to debug and modify manually.

- Binary STL: More compact and efficient, resulting in smaller file sizes and faster processing times.

ASCII STL Format

An ASCII STL file begins with a solid keyword followed by a name and then comprises several triangular facets. Each facet contains a normal vector and three vertices, representing the shape of the facet in 3D space.

Binary STL Format

Binary STL files are more common due to their reduced size and faster processing. Unlike ASCII STL files, they don’t have a human-readable format. They begin with an 80-character header followed by a four-byte unsigned integer indicating the number of triangles. Each triangular facet has a unique normal vector and vertex positions stored in binary format.

Table: ASCII vs. Binary STL

| Feature | ASCII STL | Binary STL |

|---|---|---|

| Readability | Human-readable | Not human-readable |

| File Size | Larger | Smaller |

| Speed | Slower to process | Faster to process |

| Debugging | Easier | Difficult |

| Common Usage | Less common | More common |

Essential Software for 3D Printing

When it comes to 3D printing, the STL file is just one part of the puzzle. There are various types of software involved in the entire process. Understanding the different software needed can help in achieving the desired 3D printing outcome.

Different Types of 3D Printing Software

- Modeling Software: For designing 3D models.

- CAD Software: For precise engineering and architectural designs.

- Slicer Software: For converting STL files into a format that 3D printers can interpret.

Modeling Software

Modeling software is typically used for creative purposes. It provides the tools to design intricate shapes, characters, and other artistic models.

Popular Modeling Software

- Blender: Open-source and extremely versatile, perfect for both beginners and experts.

- ZBrush: Highly specialized for detailed and complex models, often used in animation and game development.

- Tinkercad: User-friendly and web-based, great for beginners dipping their toes into 3D modeling.

CAD Software

Computer-Aided Design (CAD) software is more technically inclined. It’s widely used in engineering, architecture, and manufacturing due to its precision and functionality.

Noteworthy CAD Software

- AutoCAD: A powerhouse in the world of CAD, known for its reliability and extensive features.

- SolidWorks: Favored by engineers for its robust simulation and analysis tools.

- Fusion 360: Combines CAD, CAM, and CAE in a single package, ideal for product development.

Slicer Software

Slicer software takes the STL file and converts it into G-code, a language that 3D printers can understand. It essentially slices the 3D model into multiple layers and determines the optimal printing path.

Leading Slicer Software

- Cura: Open-source and highly customizable, widely used in the 3D printing community.

- Simplify3D: Premium software known for its advanced features and ease of use.

- PrusaSlicer: Developed by Prusa Research, optimized for their line of 3D printers but versatile enough for other models as well.

Table: Modeling vs. CAD vs. Slicer Software

| Feature/Software | Modeling Software | CAD Software | Slicer Software |

|---|---|---|---|

| Primary Use | Creative design | Engineering and precision | Converting to G-code |

| User Base | Artists, designers | Engineers, architects | 3D printing enthusiasts |

| Examples | Blender, ZBrush | AutoCAD, SolidWorks | Cura, Simplify3D |

| Ease of Use | Varies (beginner to expert) | Generally more complex | Generally more user-friendly |

How to Work with STL Files

Knowing how to manage and manipulate STL files is crucial in the 3D printing process. Here’s a step-by-step guide on how to work with STL files effectively.

Step 1: Creating the STL File

Using your choice of modeling or CAD software, you can design your 3D model. Most of these tools have a built-in feature to export 3D designs as STL files.

Exporting from Blender

- Finish your 3D design.

- Go to the “File” menu.

- Select “Export”.

- Choose “STL”.

- Save the file in your desired location.

Exporting from SolidWorks

- Complete your design.

- Click on “Save As”.

- Select “STL” from the dropdown menu.

- Save the file.

Step 2: Checking the STL File

Before moving onto slicing, it’s important to validate and, if necessary, repair the STL file. There are several tools designed to help with this.

Recommended STL Checkers

- Netfabb: Offers free and premium versions for STL repair.

- Meshmixer: Free to use and excellent for repairing holes and other common issues.

- Blender: While primarily a modeling tool, it also has mesh analysis and repair features.

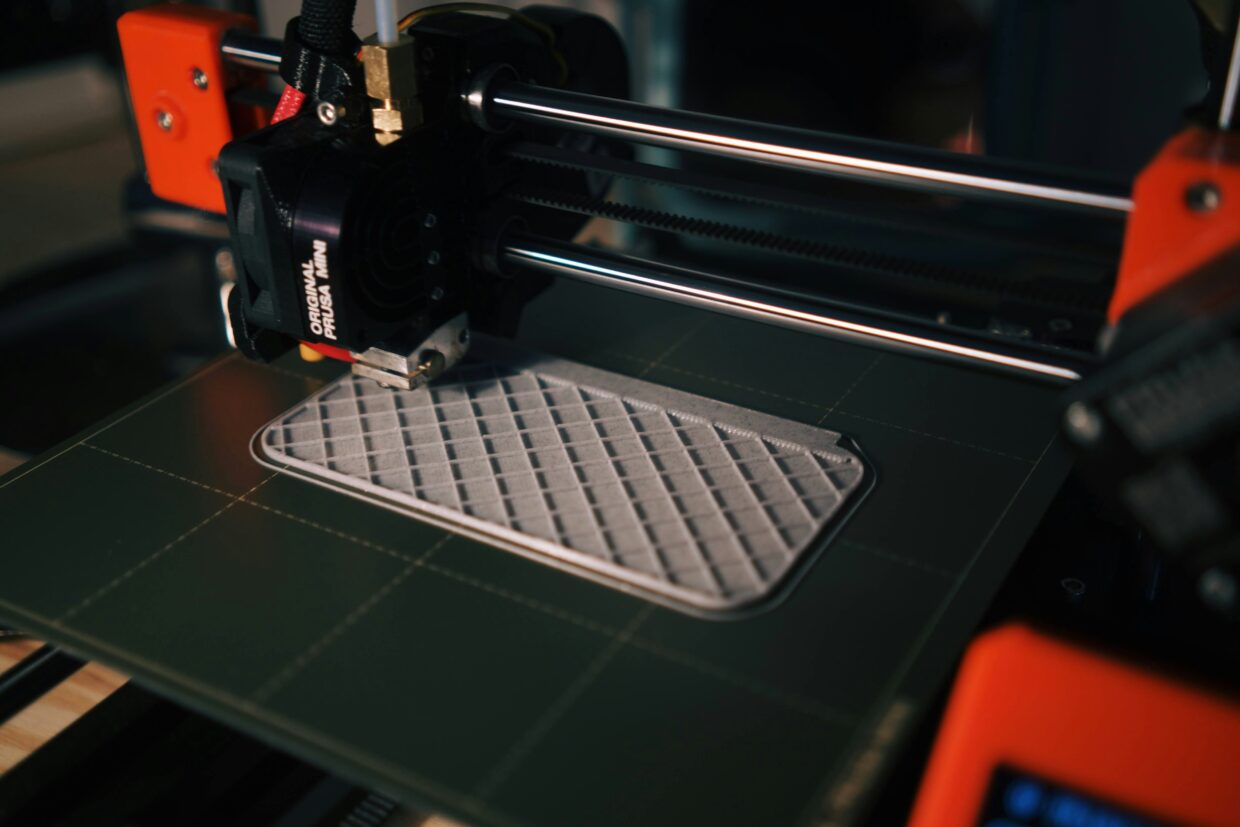

Step 3: Slicing the STL File

Load the STL file into your choice of slicer software to generate the G-code.

Using Cura

- Load your STL file into Cura.

- Choose your printer and material settings.

- Slice the file and preview the layers.

- Save the G-code to an SD card or send it directly to your 3D printer.

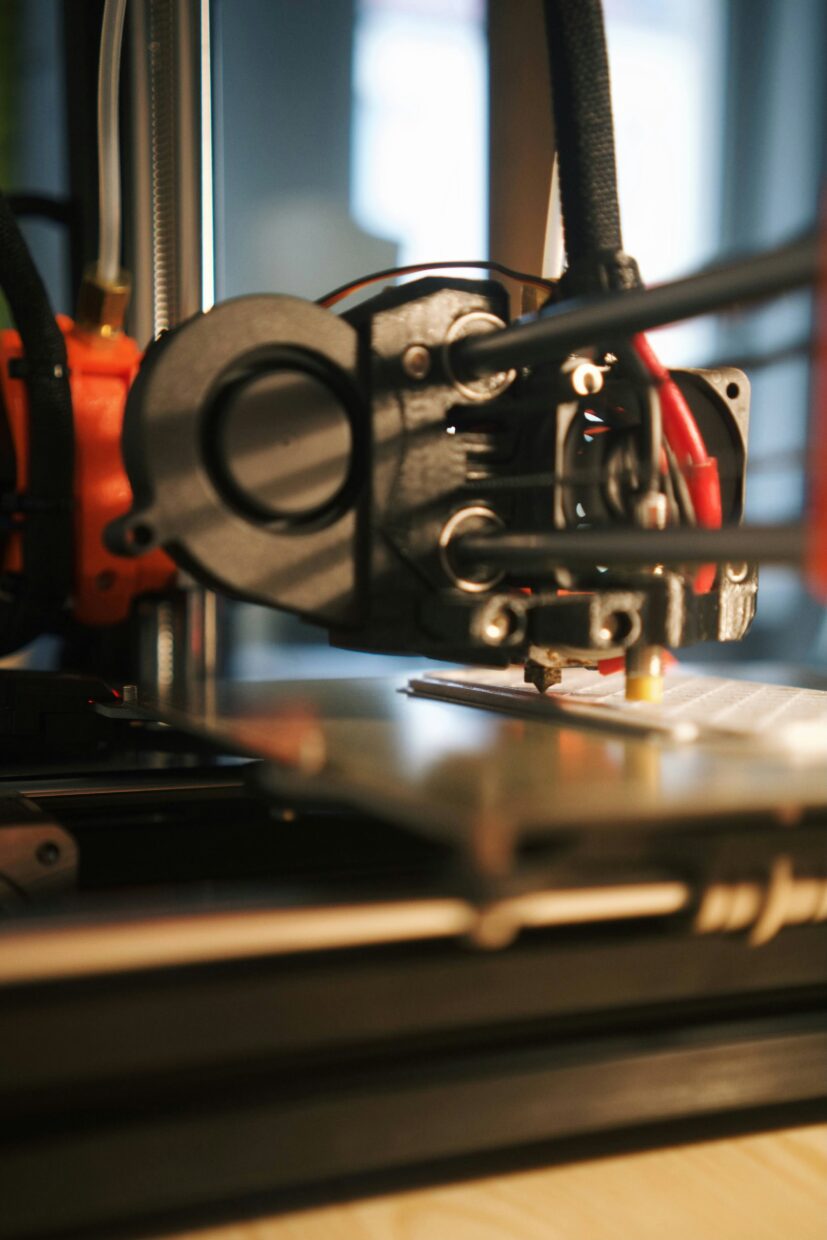

Step 4: Printing

The final step is to print the object using your 3D printer. Ensure that your printer is calibrated and ready for printing.

- Load the G-code file into your 3D printer.

- Start the print job.

- Monitor the print to ensure everything is working correctly.

Benefits of Using STL Files in 3D Printing

STL files have become the standard in 3D printing for several reasons. Here are some notable advantages:

Simplicity

The simplicity of the STL file format makes it convenient for users to create, share, and modify 3D models without needing extensive training or complex software.

Compatibility

Due to its widespread use, STL files are compatible with almost all 3D printers and slicer software, providing a seamless experience across different platforms.

Efficiency

STL files are designed to be efficient in terms of processing and file size. Binary STL files, in particular, offer highly compressed formats that accelerate slicing and printing.

Community Support

Given its popularity, there is a vast amount of resources, forums, and communities dedicated to STL files, making it easier for beginners to find support and advanced users to explore new techniques.

Limitations of STL Files

While STL files are advantageous in many ways, they come with some limitations.

Lack of Color and Texture Information

STL files only represent geometry. They do not store information about color, texture, or material properties, which can be a drawback for more complex designs requiring multiple materials or detailed appearances.

Precision Issues

Since STL files are made up of triangles, the representation might lose some finer details, especially for highly detailed or small-scale models. This can result in a loss of accuracy and might require additional tweaking.

Larger File Sizes for Complex Models

For very detailed models, STL files can become quite large, making them harder to manage and process. This is particularly true for ASCII versions, which are significantly larger compared to their binary counterparts.

Alternatives to STL Files

Despite its popularity, there are alternative file formats in the 3D printing world that mitigate some of the shortcomings of STL files.

OBJ Files

OBJ files can store color and texture information, making them ideal for more complex models requiring detailed appearances.

3MF Files

The 3D Manufacturing Format (3MF) is a relatively new file format designed to address the limitations of STL. It stores geometry, color, texture, and other information, providing a more comprehensive solution for 3D printing projects.

AMF Files

Additive Manufacturing File Format (AMF) is another alternative that supports advanced features like color and multiple materials, enhancing the scope of 3D printing applications.

Table: Comparison of 3D Printing File Formats

| Feature | STL | OBJ | 3MF | AMF |

|---|---|---|---|---|

| Geometry | Yes | Yes | Yes | Yes |

| Color | No | Yes | Yes | Yes |

| Texture | No | Yes | Yes | Yes |

| Multiple Materials | No | Yes | Yes | Yes |

| File Size | Variable | Larger | Efficient | Efficient |

| Compatibility | High | Medium | Growing | Growing |

Best Practices for Managing STL Files

To make the most out of STL files in your 3D printing endeavors, consider adopting some best practices:

Keep It Simple

While it’s tempting to create highly detailed designs, it’s often more practical to maintain a balance between detail and file size. Simplify your models where possible to ensure they are easy to work with and print efficiently.

Optimize Mesh

An optimized mesh means fewer errors during slicing and printing. Use mesh optimization tools to reduce the number of triangles without compromising the quality of the model.

Regular File Maintenance

Occasionally running checks and repairs on your STL files will help in identifying and fixing minor issues before they become major problems during printing.

Version Control

Maintain different versions of your STL files, especially if you’re making incremental changes. This will make it easier to roll back to a previous version if something goes wrong.

Use Reliable Sources

If you are downloading STL files from the internet, make sure to use reputable sources. Avoid websites that host pirated or compromised files to protect your system and guarantee quality prints.

The Future of STL Files and 3D Printing

As the technology behind 3D printing evolves, so will the tools and file formats. STL files have been a cornerstone in this industry, and while new formats like 3MF and AMF are gaining traction, STL files continue to serve a critical role in bringing ideas to life.

Emerging Trends

- Multi-Material Printing: As printers become more advanced, supporting multiple materials, colors, and textures will become standard, pushing the limitations of current file formats.

- Increased Automation: Automated slicing, error-checking, and optimization tools will streamline the entire 3D printing process, making it more accessible to a wider audience.

- Higher Resolution: Advances in printer technology will require more detailed and accurate file formats, potentially leading to enhanced versions of existing formats or completely new standards.

Community Involvement

The open-source and collaborative nature of the 3D printing community play a vital role in the ongoing development and improvement of STL files and 3D printing software. Continued community involvement will be crucial in addressing new challenges and enhancing the 3D printing ecosystem.

Conclusion

From its origins in the late 1980s to its current status as the de facto standard for 3D printing, the STL file has played an indispensable role in the world of digital fabrication. Despite some limitations, STL files provide the simplicity, efficiency, and broad compatibility needed for countless 3D printing projects. As technology progresses, the knowledge of how to effectively create, manage, and optimize these files will remain a valuable asset for hobbyists and professionals alike.

By understanding the nuances of STL files and leveraging the right software, anyone can turn their digital dreams into tangible realities. Whether you’re a budding artist, an engineer, or simply curious about 3D printing, embracing the intricacies of STL files can open up a world of creative and innovative possibilities. So the next time you marvel at a 3D-printed object, remember that it all started with a humble STL file.

About Ultimate 3D

Learn everything there is to know about 3D Printers and the different components and printing materials.

Site Links

Copyright 2024 Ultimate 3D

Be the first to leave a comment