- arrow_back Home

- keyboard_arrow_right Technology

3D Printing in Plumbing: Reducing Costs and Enhancing Efficiency

Technology Chris Wyatt 12 June 2024

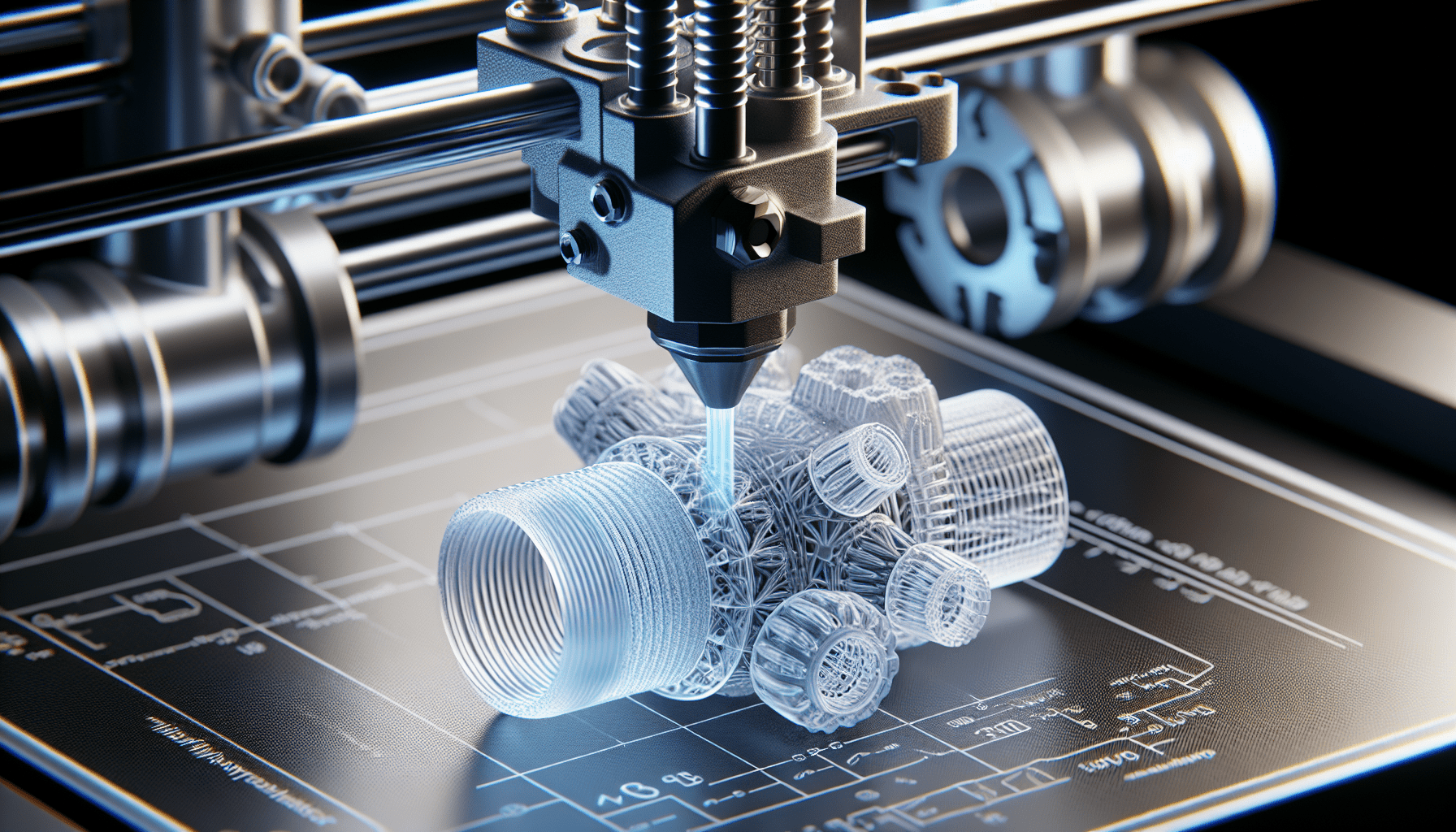

3D Printing in Plumbing: Reducing Costs and Enhancing Efficiency” explores the transformative impact of 3D printing technology within the plumbing industry. By integrating 3D printing, you can significantly reduce production costs, swiftly create custom designs, and manufacture specialized tools that enhance operational efficiency. This advanced method not only simplifies the prototyping process but also allows for the customized production of parts, ultimately providing you with more precise and cost-effective solutions in plumbing. Have you ever wondered how 3D printing could revolutionize the plumbing industry? The advent of 3D printing technology is transforming various sectors by offering unprecedented benefits, and plumbing is no exception. This sophisticated technology is reducing costs, enhancing efficiency, and allowing for rapid innovation in the creation of plumbing components and tools. If you’re eager to learn how 3D printing is reshaping plumbing, this article will provide you with a comprehensive understanding.

Understanding 3D Printing in Plumbing

3D printing, also known as additive manufacturing, refers to the process of creating a three-dimensional object from a digital file by layering materials. In the context of plumbing, 3D printing simplifies the manufacturing process and offers numerous advantages, from cost savings to improved efficiency.

How 3D Printing Works

The process begins with a digital model of the desired object, which is then converted into a series of thin horizontal layers by special software. These layers guide the 3D printer as it builds the object from the ground up, layer by layer. This method can use various materials, such as plastics, metals, and even composite materials, to create complex and custom-designed components.

Why 3D Printing is Ideal for Plumbing

Plumbing systems often require customized fittings and components, making traditional manufacturing methods both time-consuming and expensive. 3D printing addresses these challenges by offering quick and cost-effective solutions, which include:

- Customization: Designing and manufacturing bespoke parts tailored to specific plumbing requirements.

- Efficiency: Rapidly prototyping and testing new products before mass production.

- Cost Reduction: Lower production costs by reducing material waste and eliminating the need for expensive molds.

Reducing Costs with 3D Printing

One of the main advantages of 3D printing is its ability to significantly lower manufacturing costs. This is particularly valuable in the plumbing industry, where custom parts and prototypes are frequently required.

Prototyping Costs

Traditional prototyping methods involve creating molds and using them to produce parts, which can be costly and time-consuming. With 3D printing, you can produce prototypes quickly and cost-effectively. This allows for rapid iterations and modifications, resulting in a more efficient development process.

| Cost Aspect | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Initial Mold Creation | High | Low |

| Material Waste | High | Low |

| Time for Prototyping | Long | Short |

| Modifications | Expensive | Cost-effective |

3D printing slashes the costs associated with prototype development by reducing both the time and materials required, ultimately leading to faster product development cycles.

Production Costs

For mass production, 3D printing offers significant savings on both material and labor costs. Traditional manufacturing often generates considerable waste materials, which add to overall costs. In contrast, 3D printing is an additive process, using only the material needed to create each layer, thereby minimizing waste.

Furthermore, the ability to produce parts on-demand means that there is no need for large inventories, which can be costly to maintain. This on-demand production also reduces the strain on supply chains and can lead to significant savings.

Enhancing Efficiency with 3D Printing

Efficient operations are crucial in the plumbing industry, and 3D printing plays a fundamental role in optimizing various processes. From the rapid production of custom components to the ability to easily iterate designs, 3D printing significantly enhances operational efficiency.

Speed of Production

3D printing drastically reduces the time needed to produce components. What once took weeks can now be accomplished in mere hours. This rapid production capability is particularly beneficial when dealing with urgent repairs or unique challenges that require custom solutions in real-time.

Design Flexibility

Traditional methods often limit the complexity of component designs due to constraints in molding and machining. 3D printing, however, breaks these barriers by allowing for intricate and complex designs that are otherwise impossible or impractical to create. This opens up new possibilities for innovative designs and solutions that enhance the overall functionality of plumbing systems.

Inventory Management

The traditional approach to manufacturing requires maintaining large inventories to ensure the availability of parts when needed. 3D printing eliminates this necessity by enabling just-in-time production. This not only reduces storage costs but also minimizes the risk of obsolescence or excess inventory.

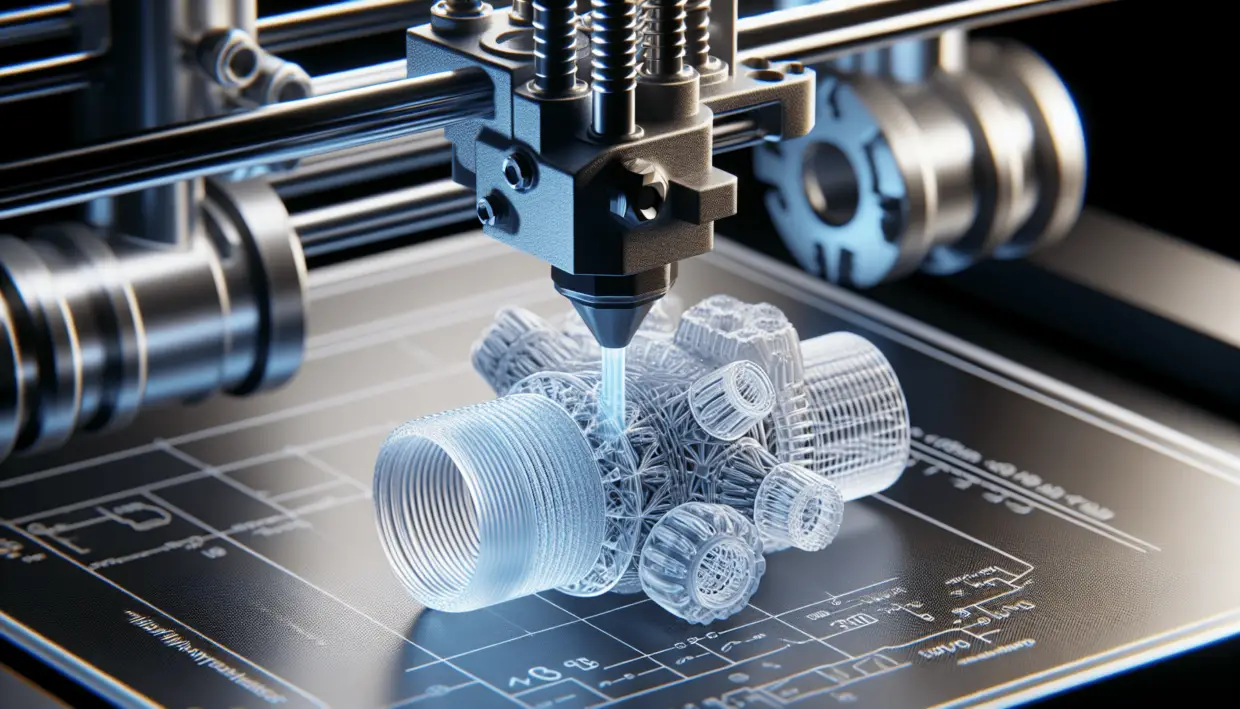

Practical Applications of 3D Printing in Plumbing

To better understand the tangible benefits of 3D printing in plumbing, let’s explore some practical applications where this technology is making a significant impact.

Custom Components

Plumbing systems often require parts that are not readily available off-the-shelf or need specific modifications. 3D printing allows for the creation of custom components designed to meet exact specifications.

Unique Fittings and Adapters

Consider a scenario where an existing plumbing system needs an adapter to connect pipes of different sizes or materials. Traditionally, finding or manufacturing such adapters could be time-consuming and costly. With 3D printing, you can swiftly design and produce the exact adapter required, ensuring a perfect fit and optimal performance.

Valve and Joint Prototypes

Valves and joints are critical components in any plumbing system. 3D printing allows for rapid prototyping and testing of these parts to ensure they meet the desired specifications. This not only accelerates the development process but also enhances the reliability and durability of the final products.

Tools and Fixtures

Apart from components and fittings, 3D printing can also be utilized to produce specialized tools and fixtures used in plumbing.

Custom Wrenches and Pliers

Imagine a scenario where a plumber needs a specific tool to access a hard-to-reach valve. Designing and printing a custom wrench or plier tailored for the job can greatly enhance efficiency and reduce downtime.

Fixtures and Templates

Fixtures used during the installation of plumbing systems can also be created using 3D printing. Custom templates and fixtures ensure precise alignment and installation, thereby improving the overall quality and reliability of the plumbing system.

Case Studies: Real-World Examples

To further illustrate the transformative impact of 3D printing in plumbing, let’s examine a couple of case studies where this technology has been successfully applied.

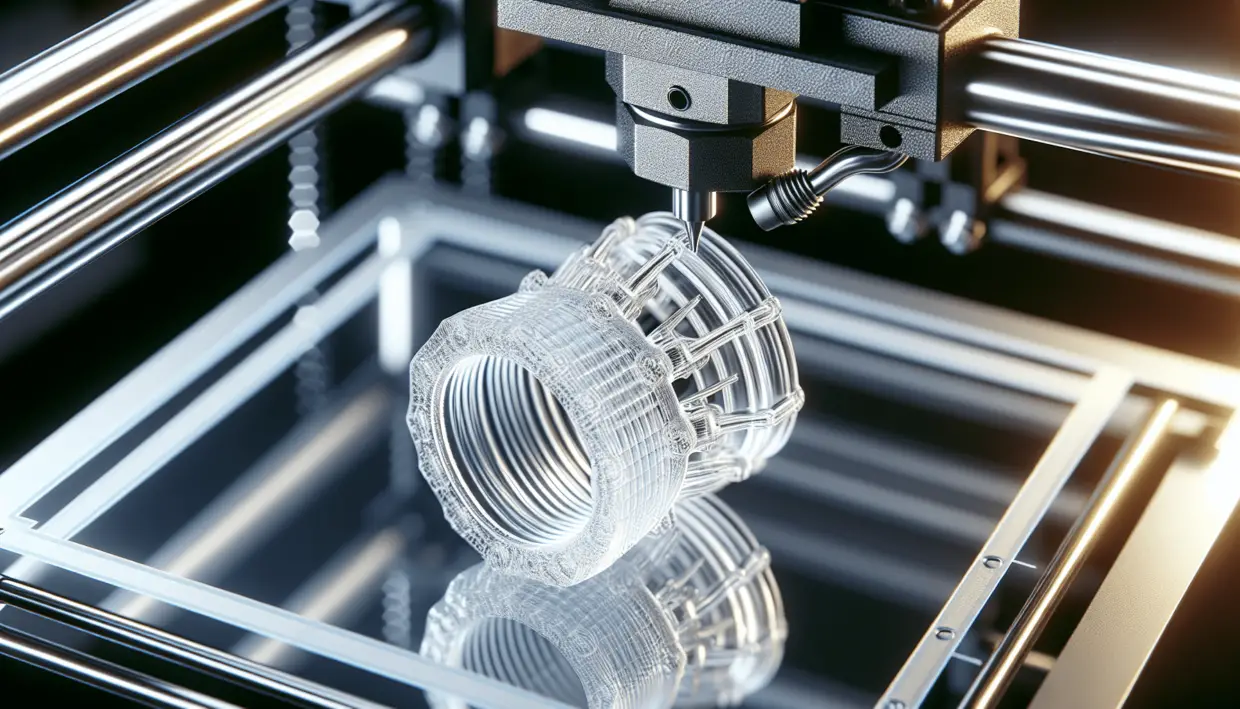

Case Study 1: Emergency Repair Solutions

In a large commercial building, a critical valve failed, causing a significant disruption to the water supply. Traditional solutions required a lead time of several weeks to manufacture and deliver a replacement part. However, with 3D printing, a custom valve was designed, printed, and installed within 24 hours, restoring normal operations and averting major losses.

Case Study 2: Innovative Designs for Water Conservation

A plumbing company was tasked with developing a new water-saving showerhead. Through rapid prototyping with 3D printing, the company was able to test multiple designs in a short period, ultimately developing a highly efficient showerhead that significantly reduced water consumption. This product not only met regulatory standards but also gained positive market reception for its innovative design.

Challenges and Considerations

While 3D printing offers numerous advantages, it’s important to acknowledge and address some challenges and considerations associated with its implementation in the plumbing industry.

Material Limitations

One of the primary considerations is the availability and suitability of materials for 3D printing. While plastics and certain metals are commonly used, some applications may require materials that are not yet feasible for 3D printing. Ongoing research and development are addressing these limitations, and new materials are continually being introduced.

Cost of Entry

Although 3D printing reduces production costs, the initial investment in high-quality 3D printers and related software can be significant. However, as technology advances and becomes more accessible, these costs are expected to decrease, making 3D printing more affordable for a broader range of applications.

| Consideration | Impact | Mitigation |

|---|---|---|

| Material Suitability | Limited by current material offerings | Ongoing R&D to develop suitable materials |

| Initial Investment | High cost of advanced 3D printing equipment | Gradual adoption, start with pilot projects |

| Training and Expertise | Need for skilled personnel to operate equipment | Training programs and hiring specialists |

Training and Expertise

Operating advanced 3D printing equipment requires specialized knowledge and skills. Companies must invest in training programs or hire experts to fully leverage the technology’s potential.

Future Prospects of 3D Printing in Plumbing

The future of 3D printing in plumbing looks promising, with continual advancements expected to further enhance its capabilities and applications.

Advancements in Material Science

Ongoing research in material science is likely to yield new materials that are more robust, durable, and suitable for a wider range of plumbing applications. This will expand the possibilities for 3D printing in creating specialized components and systems.

Integration with IoT and Smart Systems

The integration of 3D printing with the Internet of Things (IoT) and smart systems is another exciting prospect. Smart plumbing systems that can monitor and report real-time data on performance and wear can benefit greatly from 3D printed components, enabling rapid replacements and upgrades.

Sustainable and Eco-Friendly Solutions

With increasing emphasis on sustainability, 3D printing offers eco-friendly solutions by minimizing waste and enabling the use of recyclable materials. This aligns with the global push towards more sustainable and environmentally friendly practices in all industries, including plumbing.

Conclusion

3D printing is revolutionizing the plumbing industry by reducing costs, enhancing efficiency, and enabling rapid innovation. From custom components and tools to real-world applications and future prospects, this technology offers immense benefits. By overcoming current challenges and leveraging ongoing advancements, 3D printing is poised to become an integral part of the plumbing industry’s future. Embrace this technology to stay ahead of the curve and capitalize on the myriad opportunities it presents.

About Ultimate 3D

Learn everything there is to know about 3D Printers and the different components and printing materials.

Site Links

Copyright 2024 Ultimate 3D

Be the first to leave a comment